Product Details

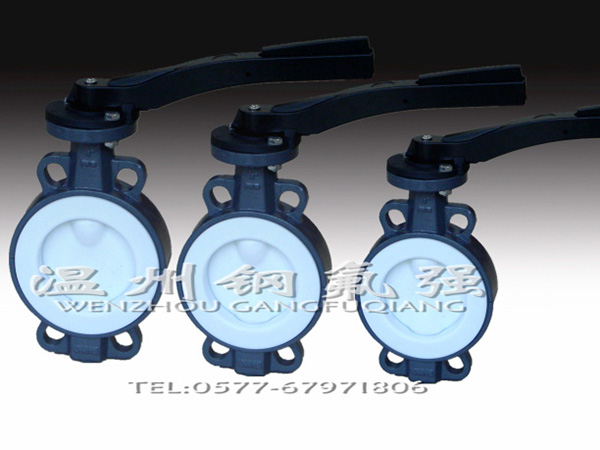

Steel lined PTFE butterfly valve

Product information

1. Product introduction

The steel-lined PTFE butterfly valve uses a butterfly plate that rotates with the valve stem as an opening and closing part to realize the opening, closing and adjustment of the valve. The steel-lined PTFE butterfly valve has compact structure, light weight, rapid opening and closing, low fluid resistance, suitable for cutting off and throttling, and has a good flow regulation effect. Compared with other valves with the same parameters, the butterfly valve reduces its weight by 30-50% on average. When the butterfly plate rotates 90°, the opening and closing process can be realized; because the butterfly plate on both sides of the rotating shaft receives the same force from the medium and the torque is opposite, the opening and closing moment is small.

2. Basic structure

When the valve is working, only the overall fluorine-lined bushing and the disc of thermally coated fluorine plastic are in contact with the medium to ensure reliable corrosion resistance: when the valve is closed, the disc squeezes the bushing to form a gapless seal.

3. Product features

1. The center line butterfly valve is that the entire butterfly plate and the valve seat are concentric within a 360° circle (center line), with a two-way sealing function, and the pressure and flow can be adjusted freely.

2. Adopting the fluorine-lined butterfly plate processed by the patented technology, the fluorine plastic and the metal matrix are tightly combined without gaps, which can effectively exhaust the interlayer bubbles and eliminate the process defects such as delamination and cracking.

3. The radial seal of the valve seat is equipped with a 360° elastic force-increasing pad, which exerts a radial restoring force, automatically adjusts the deformation, and reliably ensures that there is no internal leakage of the medium under long-term use.

4. The butterfly plate and the lower shaft shoulder adopt multi-stage loading elastic seals to realize automatic seal compensation, so that the upper and lower shaft seal pairs form no gaps and ensure no leakage of the medium.

Four, design specifications

Follow Q/320621 EXP05, GB/T 12238, API609, MSS SP-67, MSS SP-68 and other standards.

Related Information